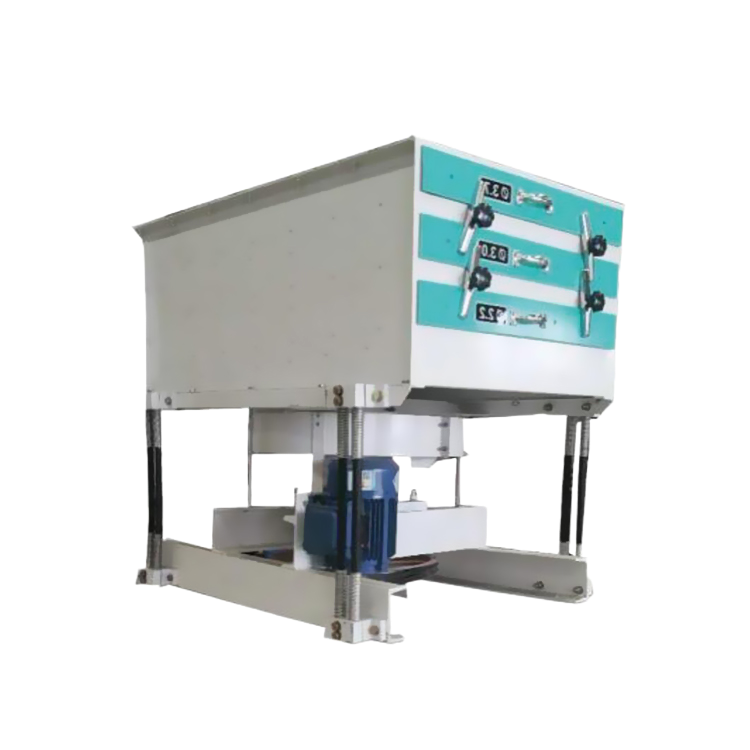

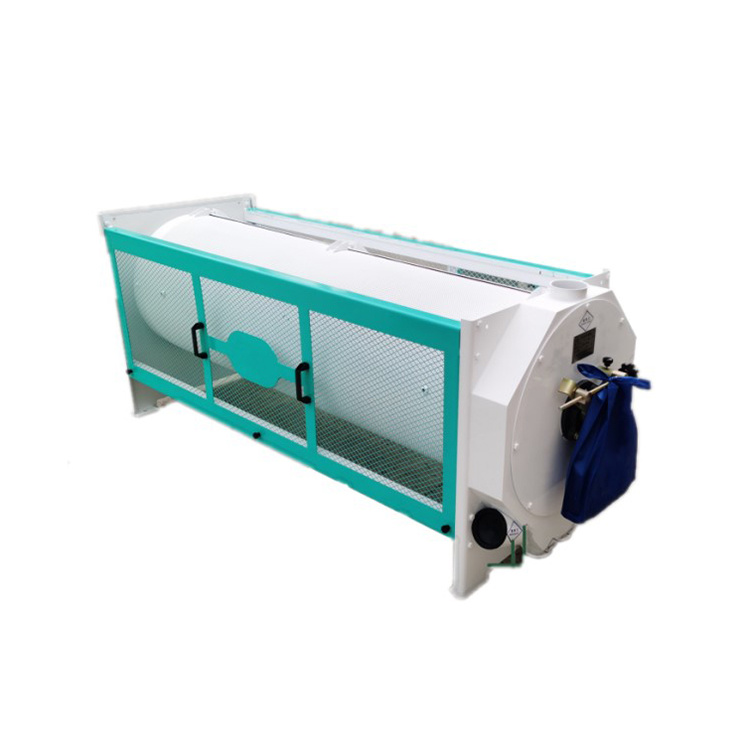

White rice grading screen

MMJP series flat to white rice grading selection screen, mainly used in rice processing plants for rice grading selection. It takes advantage of individual differences in whole rice grains. Overlapping rotation is made on the screen surface of plane rotation, and friction propulsion forms automatic classification. After proper continuous screening with screen surface, broken rice and whole rice are separated. The equipment has compact structure, stable operation, good process performance and simple operation.

Classification:

Detailed introduction

● Working principle

MMJP series flat to white rice grading selection screen, mainly used in rice processing plants for rice grading selection. It takes advantage of individual differences in whole rice grains. Overlapping rotation is made on the screen surface of plane rotation, and friction propulsion forms automatic classification. After proper continuous screening with screen surface, broken rice and whole rice are separated. The equipment has compact structure, stable operation, good process performance and simple operation.

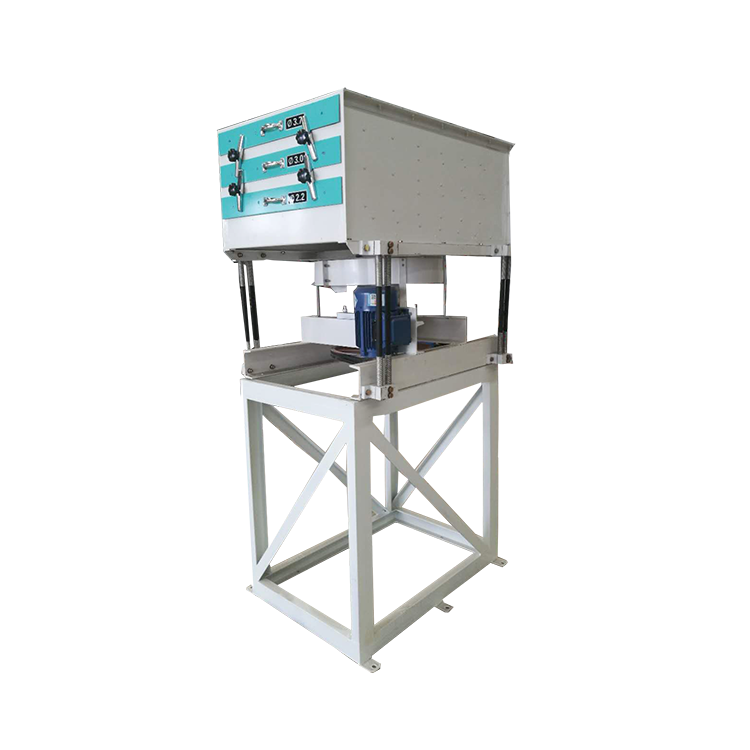

MP series flat-to-white rice grading screen is used for grading into crystal rice, which can be divided into four grades: super-grade rice, first-grade rice, large crushing and small crushing.

● Functional features

The mechanism is set up to meet the needs of the process, and it consists of two parts: speed regulating mechanism and speed regulating tensioning mechanism. The speed regulating mechanism is composed of fixed pulley, movable pulley, spring, dust cover, etc. The speed regulation tensioning structure is composed of handwheel, speed regulation screw rod, locking device, supporting seat, speed regulation nut, etc.

| Equipment Model | Yield (T/H) | Net weight of machine (kg) | Overall power (kw) | Power input (V/hz) | Exterior dimension (mm) | Wooden box packing size (mm) | Gross weight (kg) |

| MMDJ 63-3 | 1.25 | 300 | 0.75 | 380v/50Hz | 1425*740*1275 | 1525*840*1500 | 340 |

Key words:

White rice grading screen

Related recommendations

Consulting Quotation

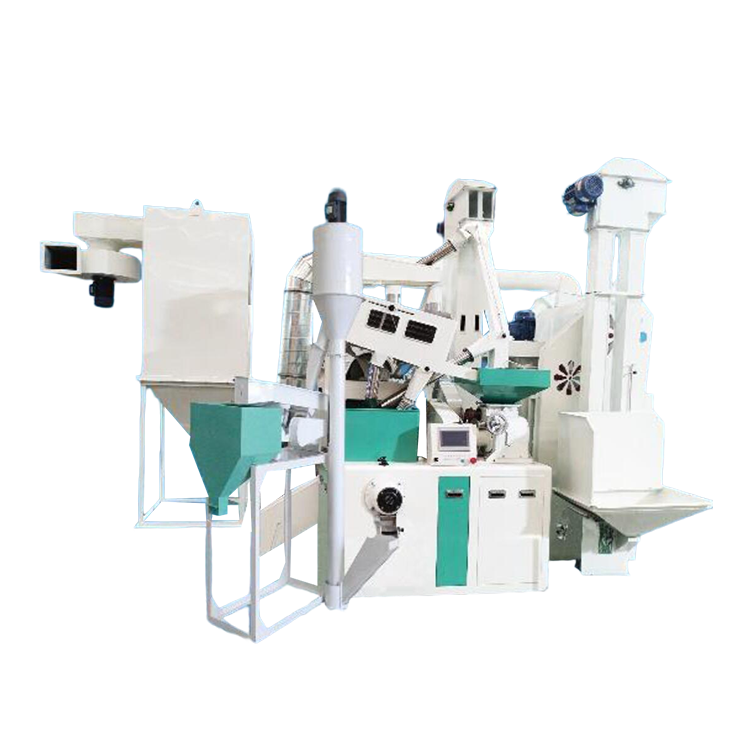

Sichuan Doujin Technology Co., Ltd, a standard-setting unit of China's fully automatic milling and milling combined rice machine, is a high-tech enterprise integrating R & D, design, production, sales, installation and maintenance.

* Note: Please be sure to fill in the information accurately and keep the communication unblocked. We will get in touch with you as soon as possible.

Language

Language